Boil

Over the past month and a half I’ve brewed four beers, starting with Piper’s Irish-American Ale , and culminating with Mr. Silly IPA which is in the middle of the mash right now. We’re less than a week from when we normally get the first snowfall that lasts until spring, so this will likely be the end of my 2012 brewing effort.

My normal process is to make a yeast starter from a Wyeast smack-pack or White Labs tube, pitch that into the first batch, and a week later siphon the chilled wort of the second batch onto the yeast cake from the first.

I didn’t have time to make a starter for Piper’s, so I just smacked the pack (Wyeast 1084, Irish Ale) on brew day and assumed there’d be enough healthy yeast to make quick work of the 1.049 wort. After two days of no visible activity, I began to worry that the yeast in the pack had been killed at some point before I bought it. Finally on day three, something finally started to happen and the beer has since fermented successfully.

The second batch was a 1.077 old ale I poured into my Old Alexi solera ale keg (recipe is here). It kicked off almost immediately and was probably 90% fermented within 24 hours due to the thick, healthy yeast from fermenting Piper’s.

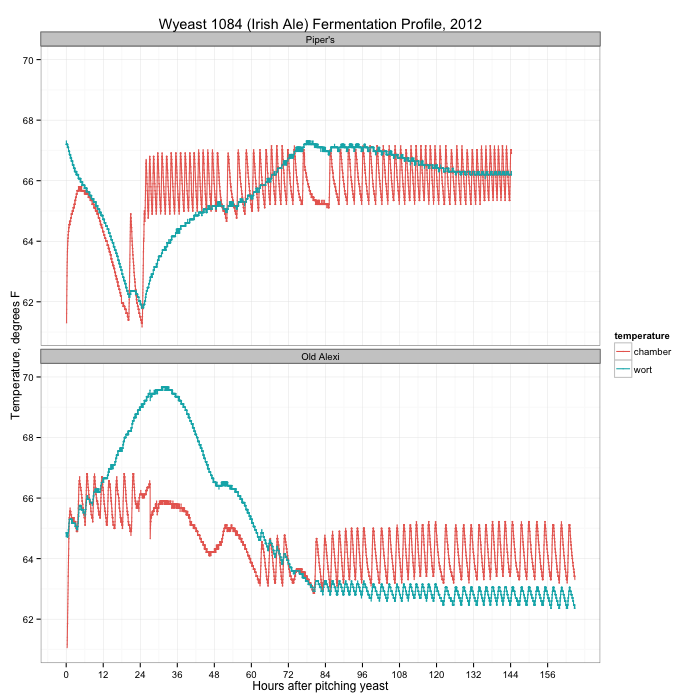

During both fermentations I kept track of the temperatures in the fermentation chamber (a fridge with heater on a temperature controller) and in the wort using my Arduino data logger. A graph of the two fermentations is below:

You can see the activity of the temperature controller on the temperature in the chamber (the orange line), clicking the heater on and off within 4 degrees of the set temperature. For Piper’s (the top plot) I started with the chamber at 64°F, but almost immediately bumped it up to 66°F when the wort temperature crashed. After 24 hours, something finally started happening in the wort, with a peak temperature (and fermentation) on day three. When I transferred the wort from primary to secondary on day seven, there was still active fermentation.

Compare this with the second beer. The wort started at 65°F, and immediately took off, peaking a little over 24 hours later. By day three, fermentation was over. I dropped the fermentation chamber temperature from 66°F to 64°F after the first day.

What did I learn? First: always make a yeast starter. It’s no fun waiting several days for fermentation to finally take off, and during that lull the wort is vulnerable to other infections that could damage the flavor. Second: don’t panic, especially with a yeast that has a reputation of starting slowly like Wyeast 1084. It usually works out in the end. More often than not, the Papazian “relax, enjoy a homebrew” mantra really is the way to approach brewing.

I used a starter for last week’s batch (Taiga Dog AK Mild, White Labs WLP007, Dry English Ale) and it was visibly fermenting within a day and a half. Mr. Silly will undoubtedly have a similar fermentation temperature curve like Old Alexi above after I transfer the wort onto the Taiga Dog yeast cake.

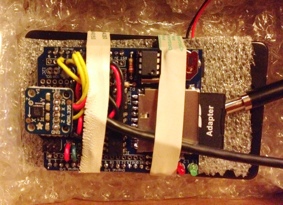

Today was the first day where I got some good data skiing to and from work using my data logger. There’s a photo of it in it’s protective box on the right. The Arduino and data logging shield (with the sensors soldered to it) is sitting on top of a battery pack holding six AA batteries. The accelerometer is the little square board that is sticking up on the left side of the logger, and you can see the SD card on the right side. The cord under the rubber bands leads to the external temperature sensor.

This morning it took about four minutes for the sensor to go from room temperature to outside temperature (-12°F), which means I need to pre-acclimate it before going out for a ski. A thermocouple would respond faster (much less mass), but they’re not as accurate because they have such a wide response range (-200°C to 1,350°C). A thermistor might be a good compromise, but I haven’t fiddled with those yet.

Here’s the temperature data from my ski home:

When I left work, the temperature at our house was 12°F, and I figured it would be warmer almost everywhere else, so I used “extra green” kick wax, which has a range of 12 to 21°F. I’ve highlighted this range on the plot with a transparent green box. In general, if you’ve chosen wax that’s too warm for the conditions, you won’t get much glide, and if the wax is rated too cold, you won’t have much kick. The plot shows that as I got near the end of the route and the temperature dropped below the lower range of the wax, I should have lost some glide, which is pretty much exactly what happened. Normally this isn’t a big issue on the Goldstream Valley Trail because it’s often very smooth, which means that a warmer wax is needed to get a grip, but this afternoon’s trail had seen a lot of snowmachine traffic, it wasn’t very smooth, and I didn’t get as much glide as earlier in the ski.

The other interesting thing is the dramatic dip marked “Goldstream Creek” on the plot. This is where the trail crosses the Creek on a small bridge designed for light recreational traffic (nothing bigger than a snowmachine or four-wheeler). It’s probably the lowest place in the trail. Our house is also on the Creek, so the two coldest spots on the trail are exactly where I’d expect them to be, right on the Creek.