Krenov-style Shelves (page 3 of 3)

This page shows the final steps in finishing my Krenov-style shelves. The most recent of these images were taken on the 12th of November, 2000. Thanks to my wife Andrea for taking such good photos of me at work.

Other Woodworking pages:

| Projects | Plans | Tools | OldTools Archive |

Virtually all the woodworking is now finished (I still need to cut

the slots in the tenons for the wedges and make a drawer for the

right side of the lower shelf), so I'm now finishing the case.

The first step is to lather on boiled linseed oil. After the oil

soaks in for a minute or two, I wipe off the excess and let the oil

dry overnight.

Virtually all the woodworking is now finished (I still need to cut

the slots in the tenons for the wedges and make a drawer for the

right side of the lower shelf), so I'm now finishing the case.

The first step is to lather on boiled linseed oil. After the oil

soaks in for a minute or two, I wipe off the excess and let the oil

dry overnight.

After the oil has dried, I pad on a 2# cut of Paddy's super blonde shellac. I use a piece of an old t-shirt wrapped around a wad of cheesecloth as my pad, and pad on about five layers on each side.

After the shellac has dried, I'm ready to begin assembling the shelves.

First I cut two slots in each tenon for wedges. The slots extend about

2/3 of the way down the tenon. If you cut them all the way, the wood

could split into the shelves and it would be visible.

After the shellac has dried, I'm ready to begin assembling the shelves.

First I cut two slots in each tenon for wedges. The slots extend about

2/3 of the way down the tenon. If you cut them all the way, the wood

could split into the shelves and it would be visible.

Before gluing the whole thing together, I made sure I knew which order things had to be assembled, and had all my cauls and clamps ready. Once the glue is out of the bottle, you've got a very limited amount of time to get everything in place. I like to use a cheap acid brush to spread a nice even coat of glue on the tenons (above).

The first step in getting everything together is putting a little

glue on the tenons of the cross piece that goes between the shelves,

and loosely fitting it. Then put glue on the right side tenons,

and carefully slip the shelves and back support into the right

side. Finally put glue on the left side tenons and fit the left side.

I couldn't get everything completely together by hand, so I used my

clamps and cauls to carefully squeeze everything together.

The first step in getting everything together is putting a little

glue on the tenons of the cross piece that goes between the shelves,

and loosely fitting it. Then put glue on the right side tenons,

and carefully slip the shelves and back support into the right

side. Finally put glue on the left side tenons and fit the left side.

I couldn't get everything completely together by hand, so I used my

clamps and cauls to carefully squeeze everything together.

The last step before letting everything dry is to hammer in the

wedges into the tenon slots. I used very thinly cut purpleheart

strips (cut at about a degree) for my wedges. Because the sides

of my shelves had already cracked once, I used thin wedges, and I'm

not depending on them to do anything but fully seat the tenon sides

in the mortise.

The last step before letting everything dry is to hammer in the

wedges into the tenon slots. I used very thinly cut purpleheart

strips (cut at about a degree) for my wedges. Because the sides

of my shelves had already cracked once, I used thin wedges, and I'm

not depending on them to do anything but fully seat the tenon sides

in the mortise.

Once the glue dried I applied several more coats

of shellac to all the exterior surfaces. After a week I sanded the

exterior surfaces with 600 grit sandpaper wetted with soapy water, and

smoothed the light scratch marks with #0000 steel wool. Finally, a

light coat of paste wax, and the shelves are finished!

Once the glue dried I applied several more coats

of shellac to all the exterior surfaces. After a week I sanded the

exterior surfaces with 600 grit sandpaper wetted with soapy water, and

smoothed the light scratch marks with #0000 steel wool. Finally, a

light coat of paste wax, and the shelves are finished!

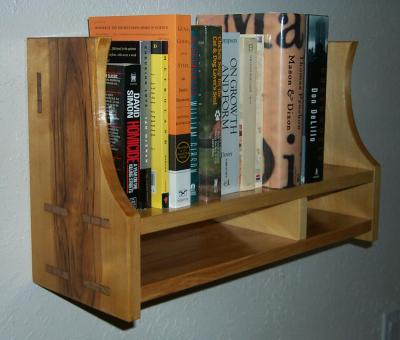

Here's the shelves hanging on the wall. I haven't built the little drawer that will fit into the right space beneath the bookshelves, but I need to refine my dovetailing skills first!

![[ Swingley Development ]](../images/title.png)